FLEXIBLE INTERMEDIATE BULK

FIBC bags, also known as Flexible Intermediate Bulk Containers or bulk bags, are large, durable, and flexible storage containers widely used in various industries for transporting and storing bulk materials.

- Information

FIBC bags, also known as Flexible Intermediate Bulk Containers or bulk bags, are large, durable, and flexible storage containers widely used in various industries for transporting and storing bulk materials. These bags are designed to handle heavy loads and are an efficient and cost-effective solution for packaging and transporting goods.

FIBC bags are made from woven polypropylene (PP) or polyethylene (PE) fabric, which provides them with exceptional strength and durability. The fabric is woven in such a way that it can withstand the weight of the contents and resist tearing or puncturing. The bags also have lifting loops or handles attached to them, making them easy to handle and transport using forklifts or cranes.

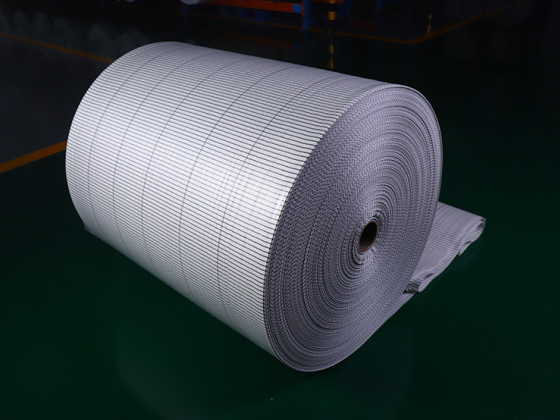

One of the key advantages of FIBC bags is their large storage capacity. These bags can hold anywhere from 500 to 4000 liters of material, depending on their size and design. This makes them ideal for transporting and storing a wide range of materials, including grains, powders, chemicals, minerals, and construction materials.

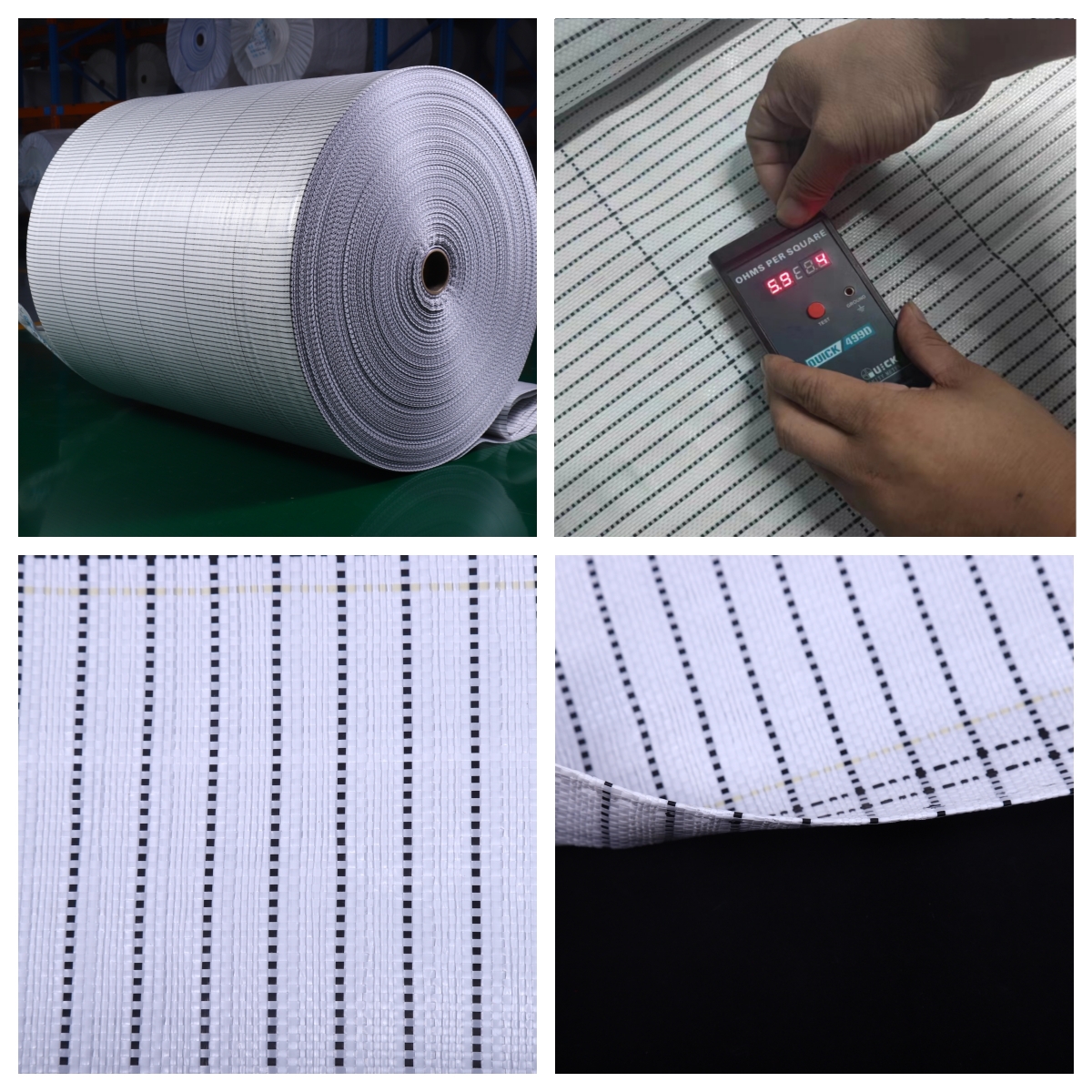

Product usage: TYPE-C type container bag is also called conductive flexible container bag, or grounded flexible container bag. Originally woven from a completely conductive material. Nowadays, grounded C-shaped flexible container bags are more often made of non-conductive polypropylene fabrics interspersed with conductive blended fabrics, usually woven in a grid-like pattern. This conductive woven fabric must be interconnected internally, and when using a TYPE-C container bag, the black conductive film on the bag body must be connected to the ground to conduct electricity through the ground, effectively removing the electrical energy generated during loading and unloading. Static electricity to prevent dangerous situations such as burning and explosion.

It is widely used in the food, pharmaceutical and chemical industries and can be used to fill, store and transport solid, powder, granular, flake and other products.

Production Process:

Raw materials → Drawing → Circular weaving → Inspection → Packaging → Warehousing