Polyethylene Fabric Bags

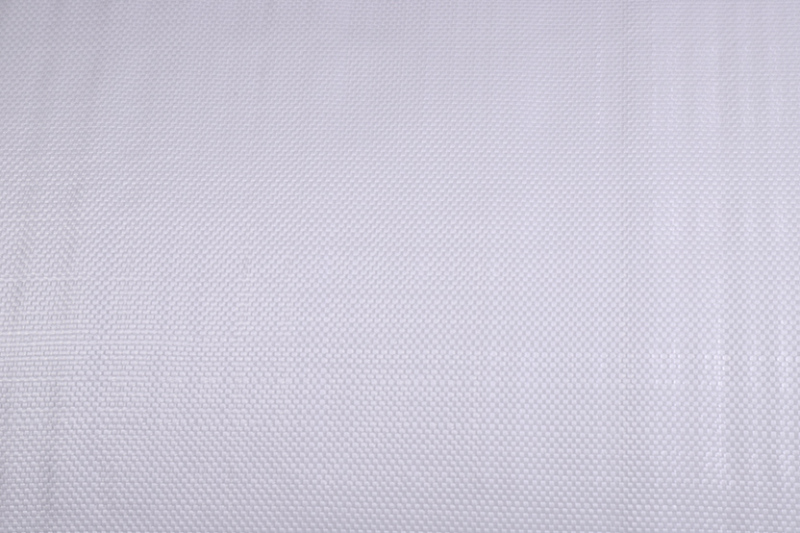

FIBC bags are made from woven polypropylene (PP) or polyethylene (PE) fabric, which provides them with exceptional strength and durability. The fabric is woven in such a way that it can withstand the weight of the contents and resist tearing or puncturing.

- Information

FIBC bags are made from woven polypropylene (PP) or polyethylene (PE) fabric, which provides them with exceptional strength and durability. The fabric is woven in such a way that it can withstand the weight of the contents and resist tearing or puncturing. The bags also have lifting loops or handles attached to them, making them easy to handle and transport using forklifts or cranes.

The anti-static container bag base fabric is also made of Type A weaving links. However, the breakdown voltage of the woven fabric of TypeB bags cannot exceed 4KV. This means that the Type B container bag will not generate propagating brush discharge. This is an important classification, which means that few discharges that can be generated on container bags are low energy brush discharges. If the propagation type brush discharge can be excluded, and the super energy of the brush discharge is 4mJ, it is reasonable to believe that this type of container bag is safe for the combustible gas environment where the ultra small ignition energy does not exceed 4mJ. Similarly, for combustible dust with ignition energy not exceeding 4nd, this type of container bag is also safe. However, Type B container bags cannot be used in flammable hydrocarbon vapor environments. It must be noted that some factories produce container bags that meet the classification criteria of Type B, but they can still cause accidents. For example, when tested by a testing agency, it meets the Type B standard. However, in practical use, due to the coating on the inner lining bag and bag surface, the breakdown voltage is higher than 4KV, resulting in the Type B bag actually becoming Type A.

Product Usage:

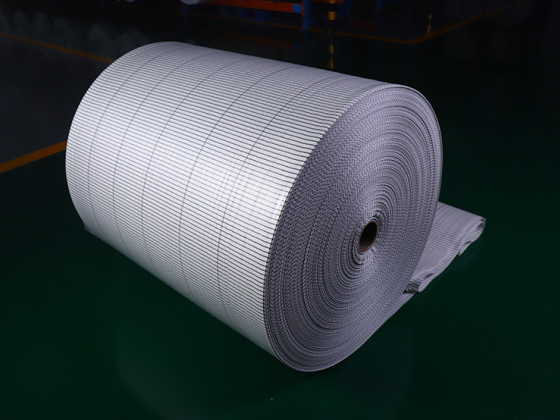

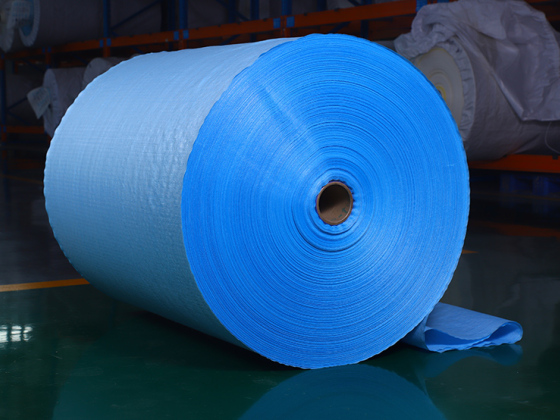

This product is made by mixing PP (polypropylene) particles and plastic modifiers through drawing, circular weaving and other processes. It is an important raw material in the production process of container bags (ton bags, ton bags) - base fabric ( Also called woven cloth). Commonly used in packaging of food, medicine, chemicals, minerals, etc. This product can be customized according to the specific needs and personalization of customers and container bags in terms of size, ratio, weight, color, etc.

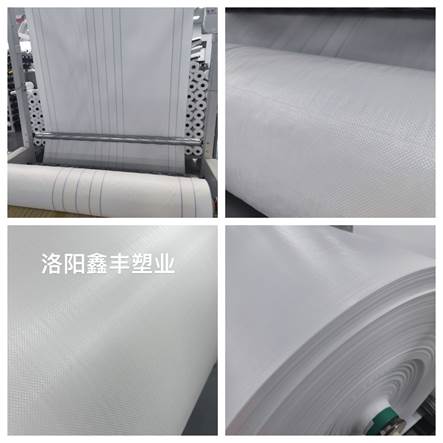

Production Process:

Raw materials → Drawing → Circular weaving → Inspection → Packaging → Warehousing