- Home

- >

- Products

- >

- BAFFLE FIBC BAG

- >

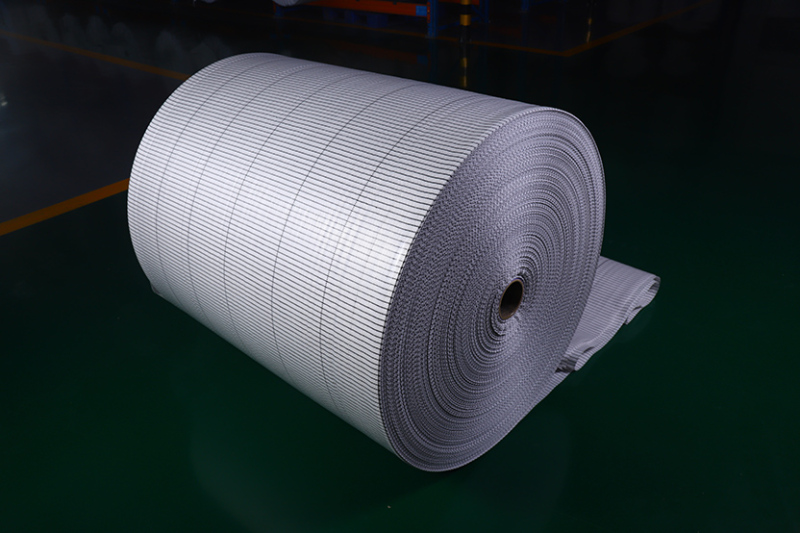

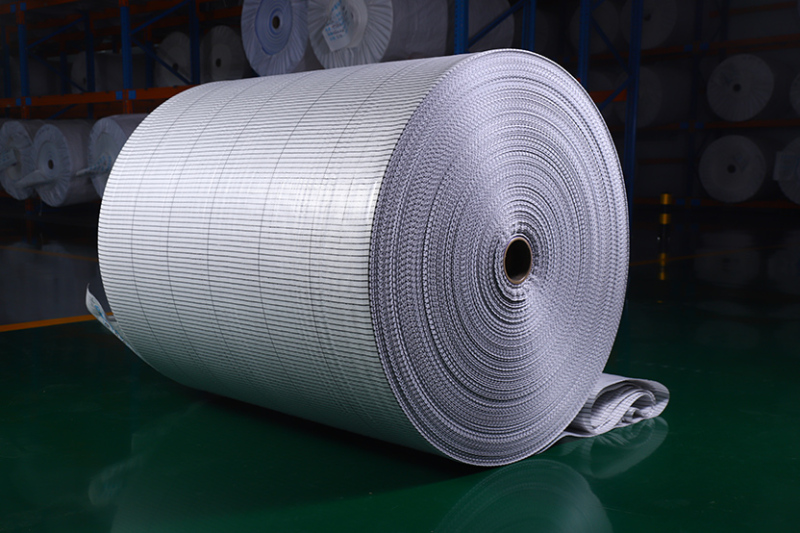

BAFFLE FIBC BAG

The use of FIBC bags offers several advantages. Firstly, they are reusable and recyclable, making them an environmentally friendly choice. Secondly, their design allows for efficient loading and unloading, reducing labor and time costs. Moreover, their flexibility enables easy storage and transportation, as they can be stacked or folded when empty, saving space.

- Information

FIBC bags come in various types and designs to suit different requirements. Some common types include standard bags, conductive bags (for materials that are sensitive to static electricity), and food-grade bags (for storing food products). Additionally, FIBC bags can be customized with features such as liners, spouts, or baffles to enhance their functionality and meet specific needs.

The use of FIBC bags offers several advantages. Firstly, they are reusable and recyclable, making them an environmentally friendly choice. Secondly, their design allows for efficient loading and unloading, reducing labor and time costs. Moreover, their flexibility enables easy storage and transportation, as they can be stacked or folded when empty, saving space.

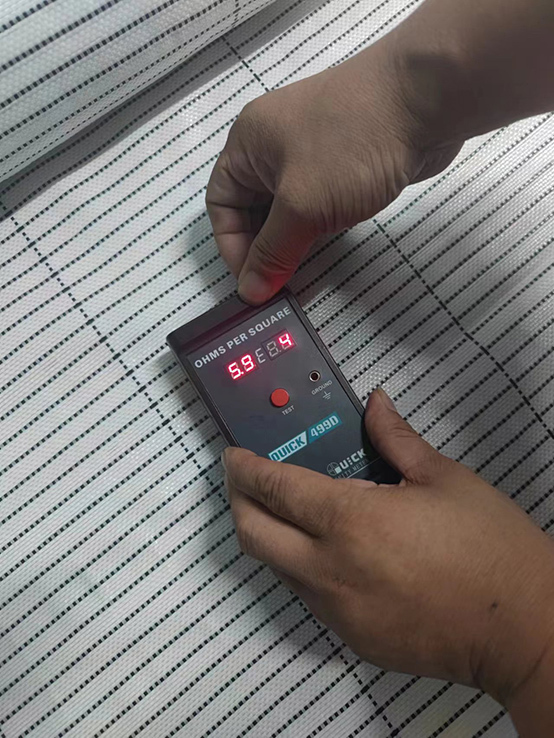

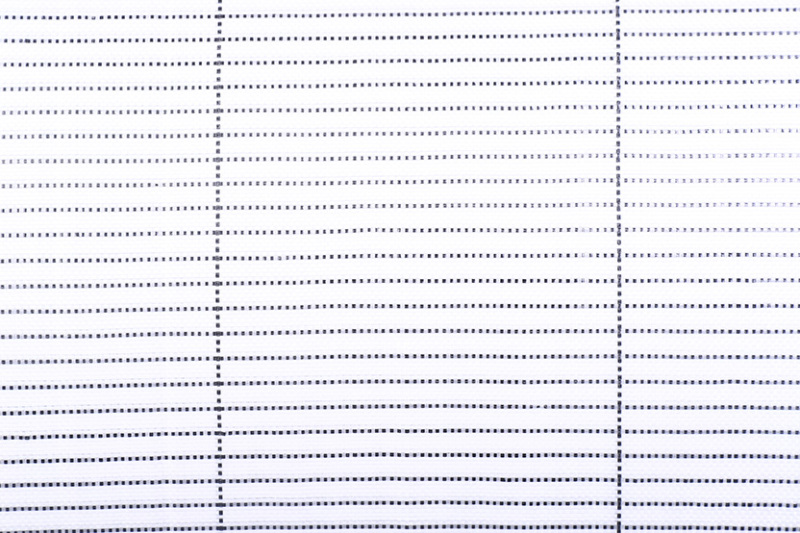

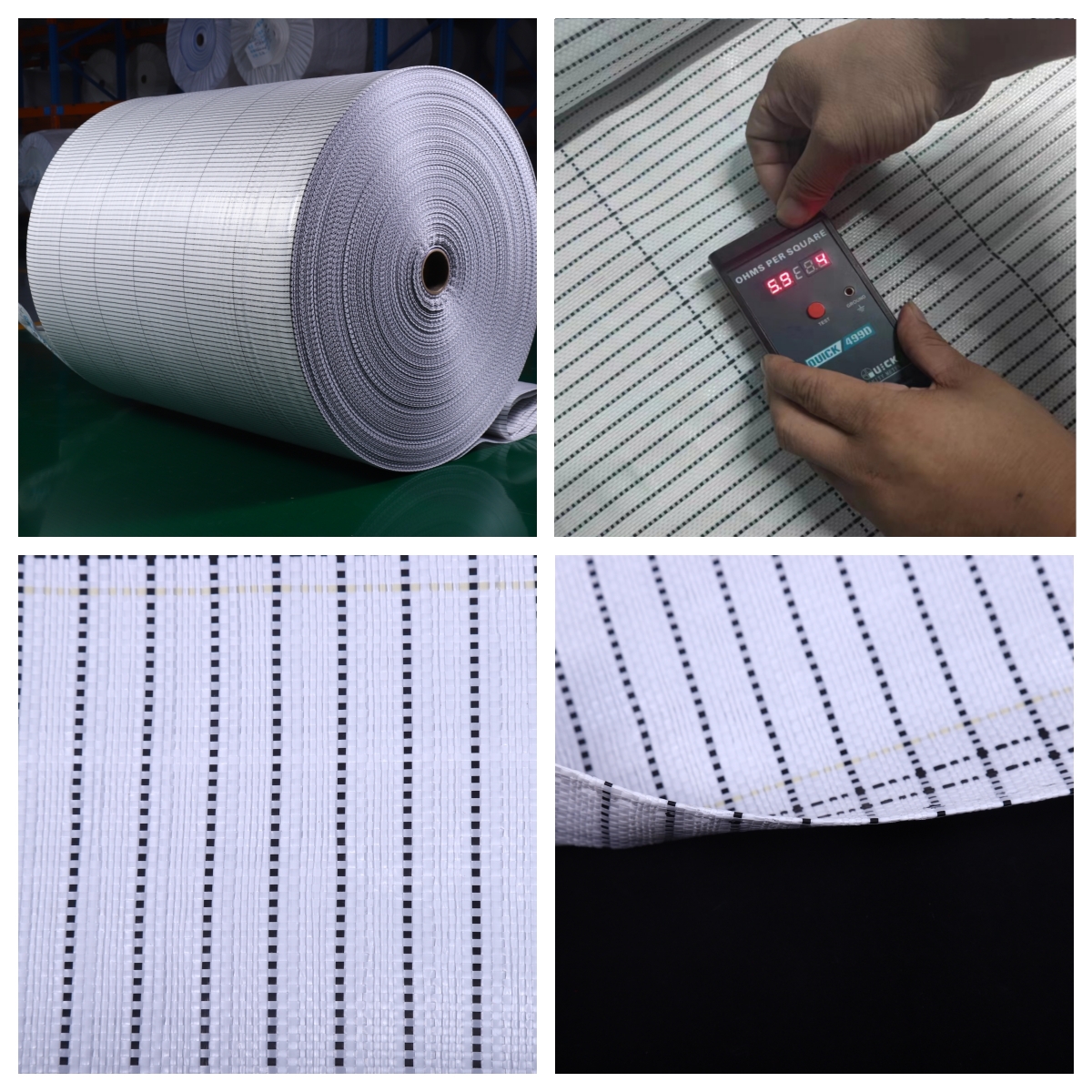

The Type C anti-static container bag base fabric is designed for sensitive and flammable environments, including flammable hydrocarbon solvent vapor environments. This type of container bag base fabric is made of conductive fabric or woven fabric coated with conductive/anti electric coating. Conductive cloth is actually a woven fabric interwoven with conductive fibers/flat wires. In some designs, the conductive wires are parallel with a spacing of 20mm. A higher demand design is to weave conductive wires into a network shape, with the wires intersecting vertically.

Product usage: TYPE-C type container bag is also called conductive flexible container bag, or grounded flexible container bag. Originally woven from a completely conductive material. Nowadays, grounded C-shaped flexible container bags are more often made of non-conductive polypropylene fabrics interspersed with conductive blended fabrics, usually woven in a grid-like pattern. This conductive woven fabric must be interconnected internally, and when using a TYPE-C container bag, the black conductive film on the bag body must be connected to the ground to conduct electricity through the ground, effectively removing the electrical energy generated during loading and unloading. Static electricity to prevent dangerous situations such as burning and explosion.

It is widely used in the food, pharmaceutical and chemical industries and can be used to fill, store and transport solid, powder, granular, flake and other products.

Production Process:

Raw materials → Drawing → Circular weaving → Inspection → Packaging → Warehousing