ABOUT US

Luoyang Xinfeng Plastic Industry Co., Ltd. is located in Luoyang City, the ancient capital of thirteen dynasties in Henan Province, China, with a long history. Luoyang Xinfeng Plastic Industry Co., Ltd. is located between Youchou Luoshui and the towering Mang Mountain, at the entrance of Shiqiao Village, Shouyangshan Town.

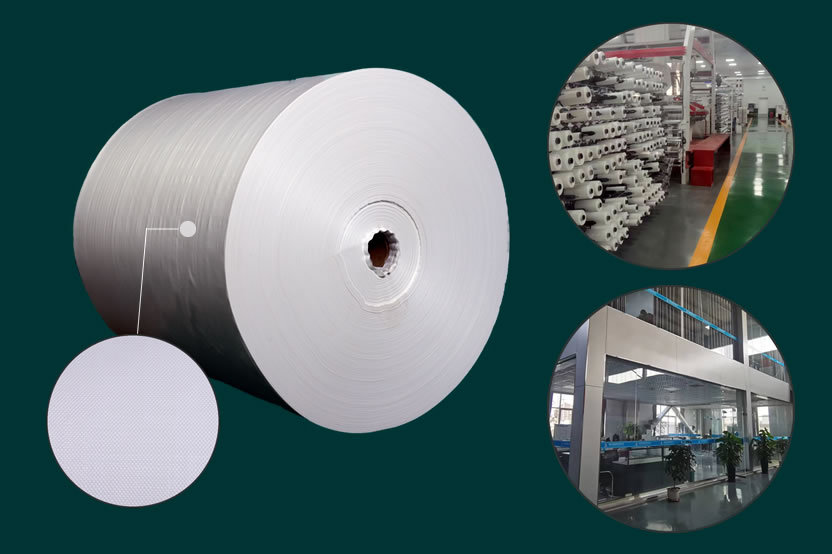

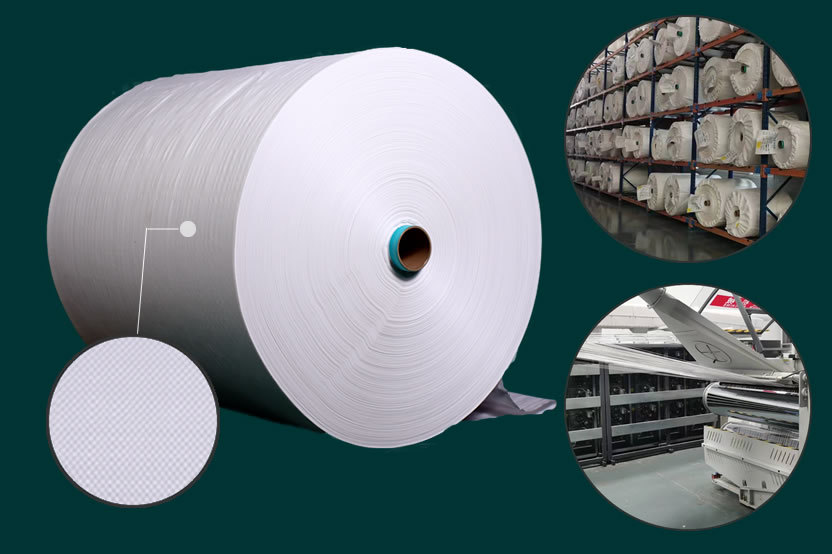

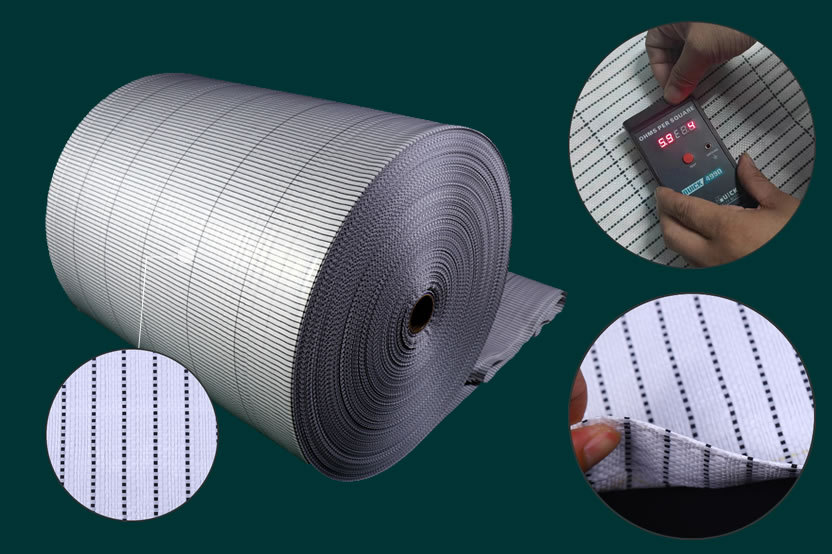

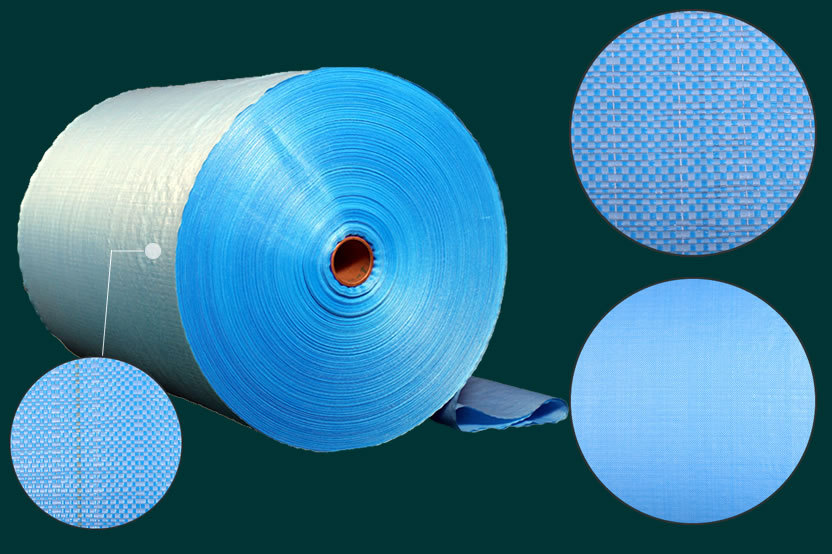

Luoyang Xinfeng Plastic Industry Co., Ltd. mainly produces and sells food-grade container bag auxiliary materials (base fabric, sling products), with an annual output of more than 8,000 tons. From wire drawing, weaving, ribbon, inspection, packaging and other complete production and processing, it has a complete set of testing methods and food-grade certification to ensure quality. Luoyang Xinfeng Plastic Industry Co., Ltd. has a clean workshop of nearly 10,000 square meters. The company has passed the "National Industrial Product Production License" and related quality system certifications.