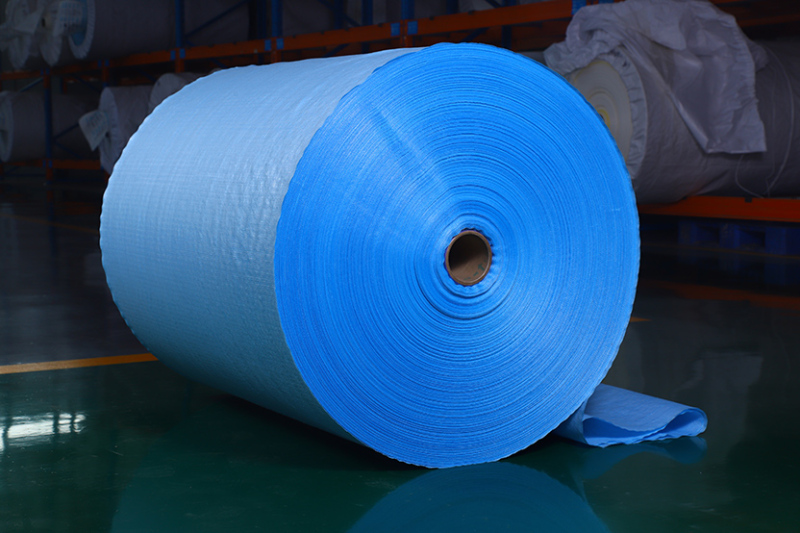

CONTAINER BAG BASE FABRIC TYPE D

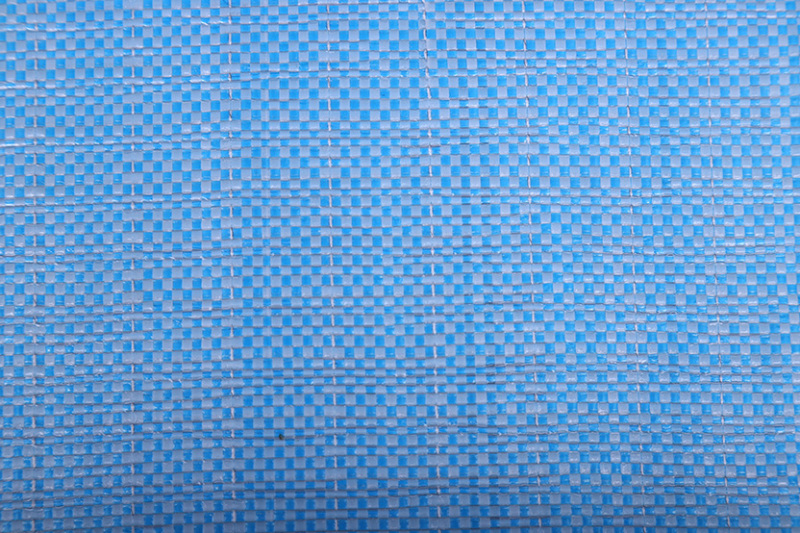

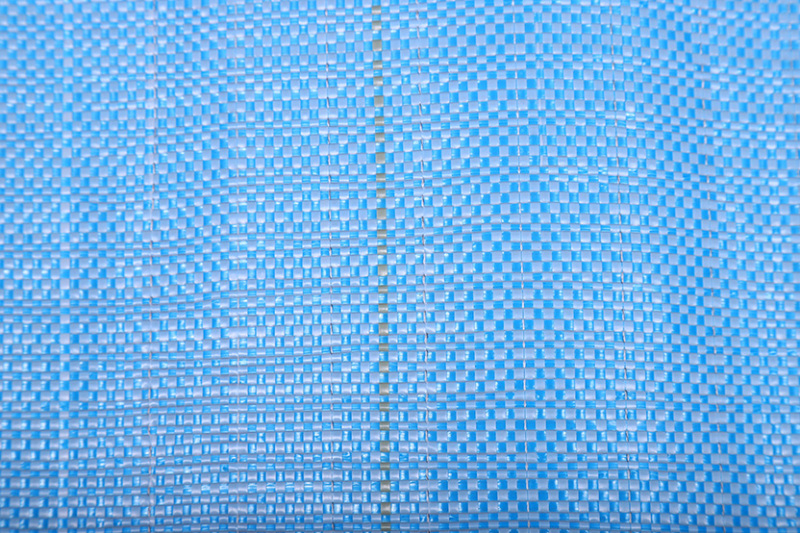

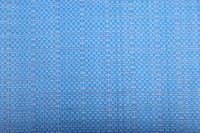

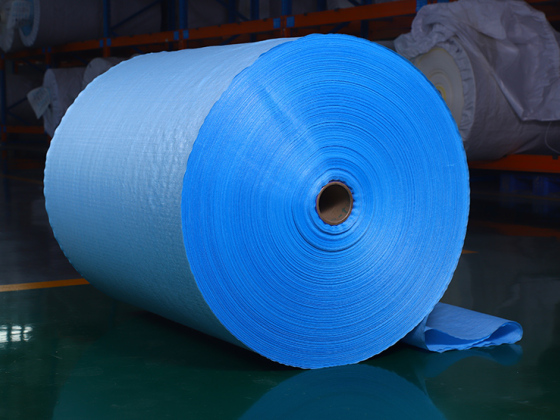

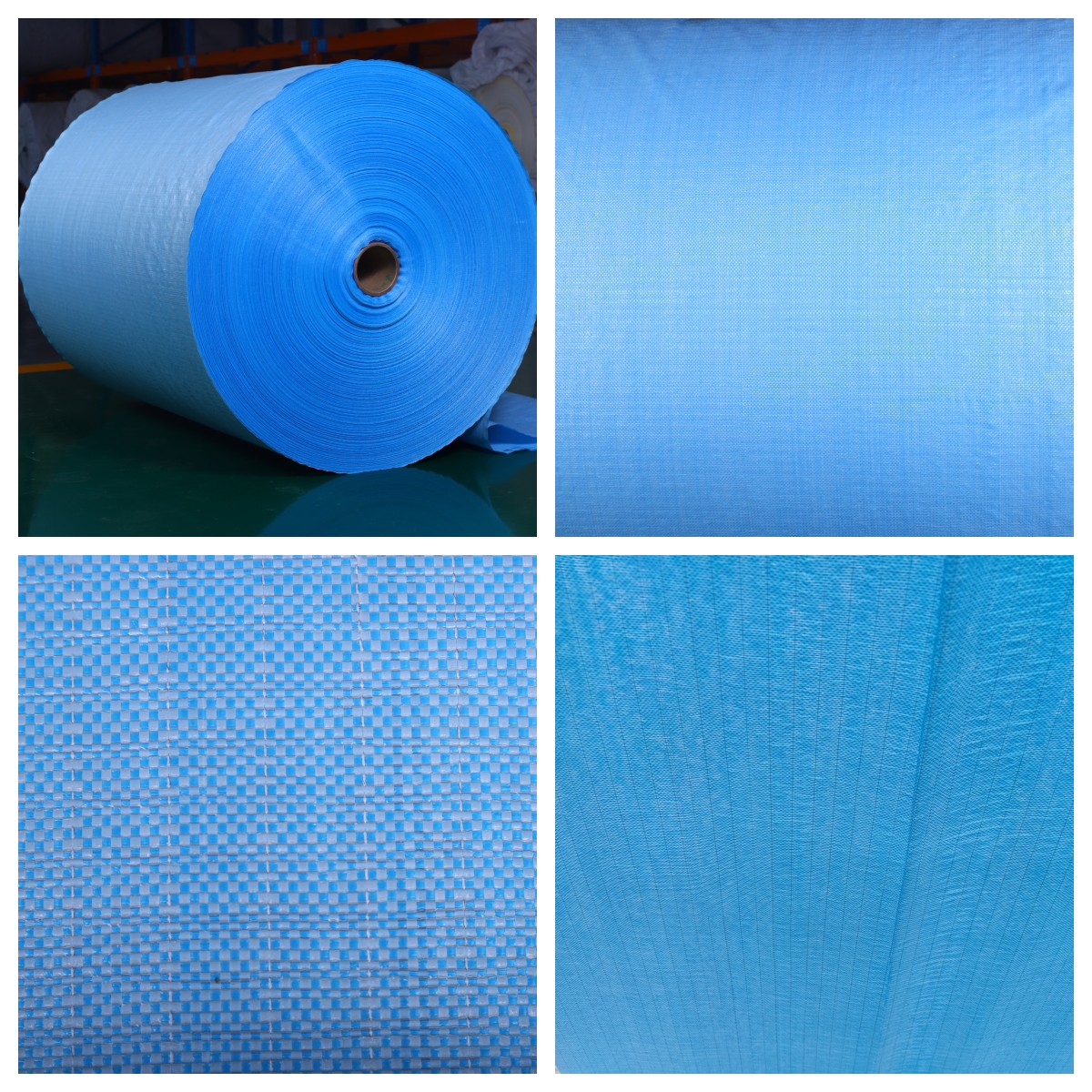

The base fabric of Type D conductive container bags should have anti-static or electrostatic dissipation characteristics, without the need for grounding, and is usually synthesized using nylon fiber yarn. Most of the Type D container bags on the market today are made by interweaving thin semi conductive wires into woven fabric. Unlike the design of Type C container bags, these semi conducting wires, although parallel in meridional direction, are not cross-linked. Conductive wire is usually composed of conductive metal coating or conductive metal wire. This type of container bag will have an electrostatic elimination coating, so we usually refer to it as a conductive container bag.

- Information

The base fabric of Type D conductive container bags should have anti-static or electrostatic dissipation characteristics, without the need for grounding, and is usually synthesized using nylon fiber yarn. Most of the Type D container bags on the market today are made by interweaving thin semi conductive wires into woven fabric. Unlike the design of Type C container bags, these semi conducting wires, although parallel in meridional direction, are not cross-linked. Conductive wire is usually composed of conductive metal coating or conductive metal wire. This type of container bag will have an electrostatic elimination coating, so we usually refer to it as a conductive container bag. Due to its complex manufacturing process, the price is higher first.

Type D container bag is woven with electrostatic protection fabric,without grounding,can avoid ignition spark discharge,brush discharge and propagation brush discharge.Type D container bag can avoid igniting spark discharge,brush discharge and propagating brush discharge.It can be safely used for packing combustible materials and handling cargo in flammable and flammable environment