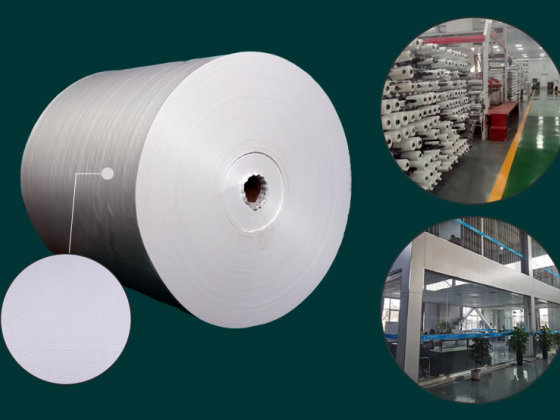

FIBC TYPE-A BASE FABRIC

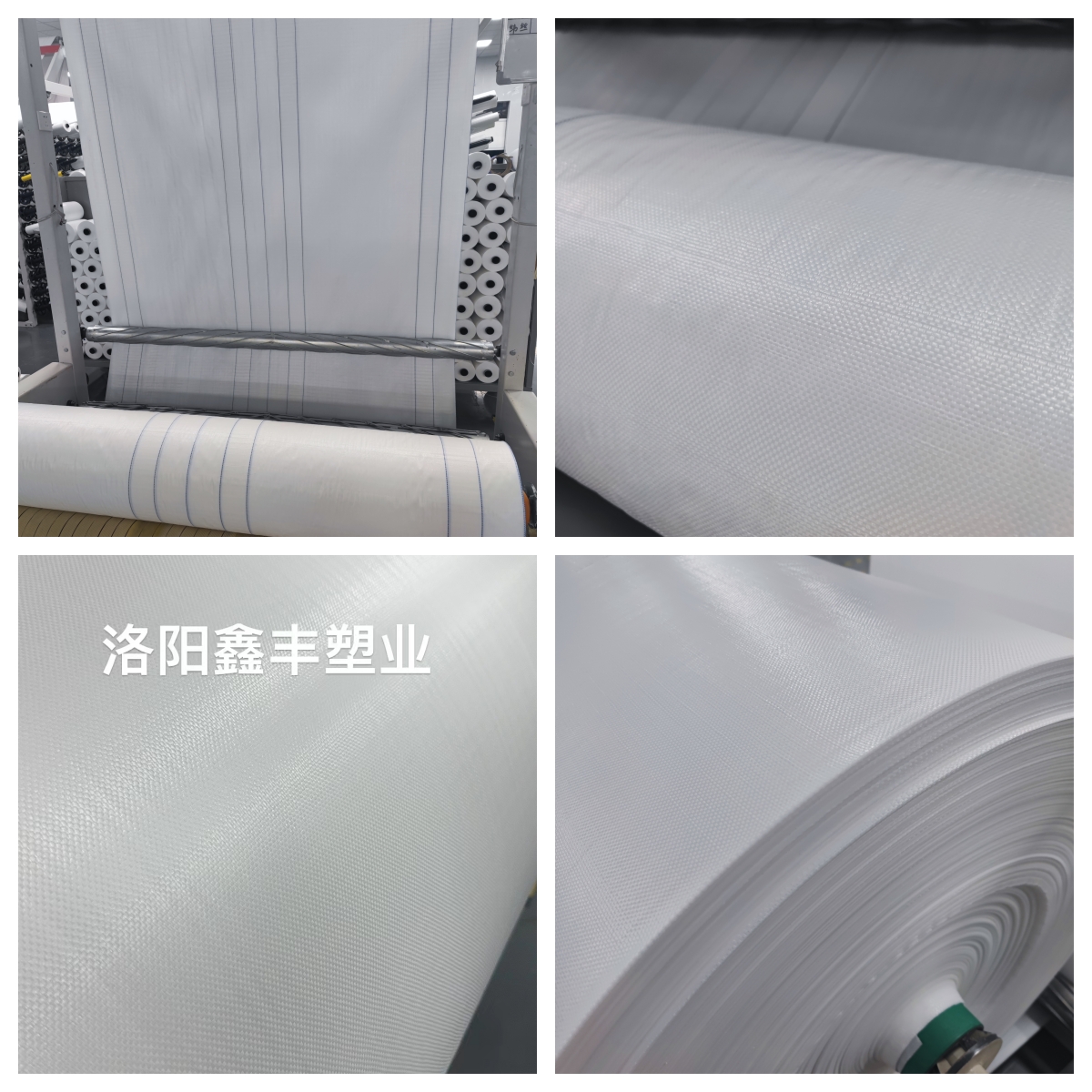

Polypropylene PP particle drawing is used to extrude, stretch, shape, and roll up the warp and weft threads according to the standard width, denier number, and thickness through a high-speed drawing machine.

- Information

Polypropylene PP particle drawing is used to extrude, stretch, shape, and roll up the warp and weft threads according to the standard width, denier number, and thickness through a high-speed drawing machine. After passing the quality inspection, the circular weaving workshop will carry out wire arrangement, threading, installation of corresponding size rings, debugging, grinding, and winding to complete the initial production steps of the base fabric. After the visual and dust removal equipment inspection of the fabric is completed through quality inspection again, the wrapping packaging and outer packaging are wrapped and stored in the warehouse.

This product is made by mixing PP (polypropylene) particles and plastic modifiers through drawing, circular weaving and other processes. It is an important raw material in the production process of container bags (ton bags, ton bags) - base fabric ( Also called woven cloth). Commonly used in packaging of food, medicine, chemicals, minerals, etc. This product can be customized according to the specific needs and personalization of customers and container bags in terms of size, ratio, weight, color, etc.

Production Process

Raw materials → Drawing → Circular weaving → Inspection → Packaging → Warehousing